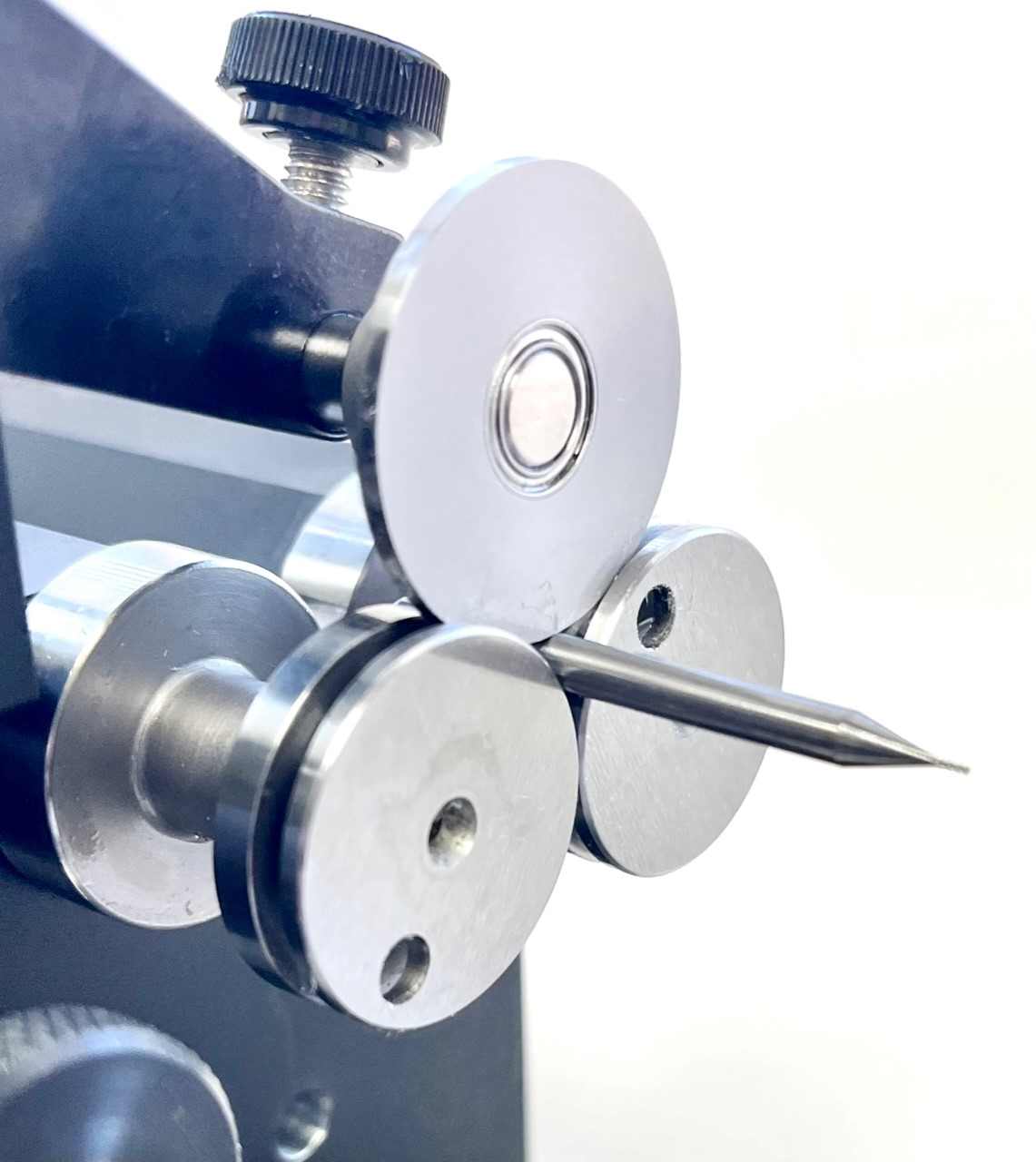

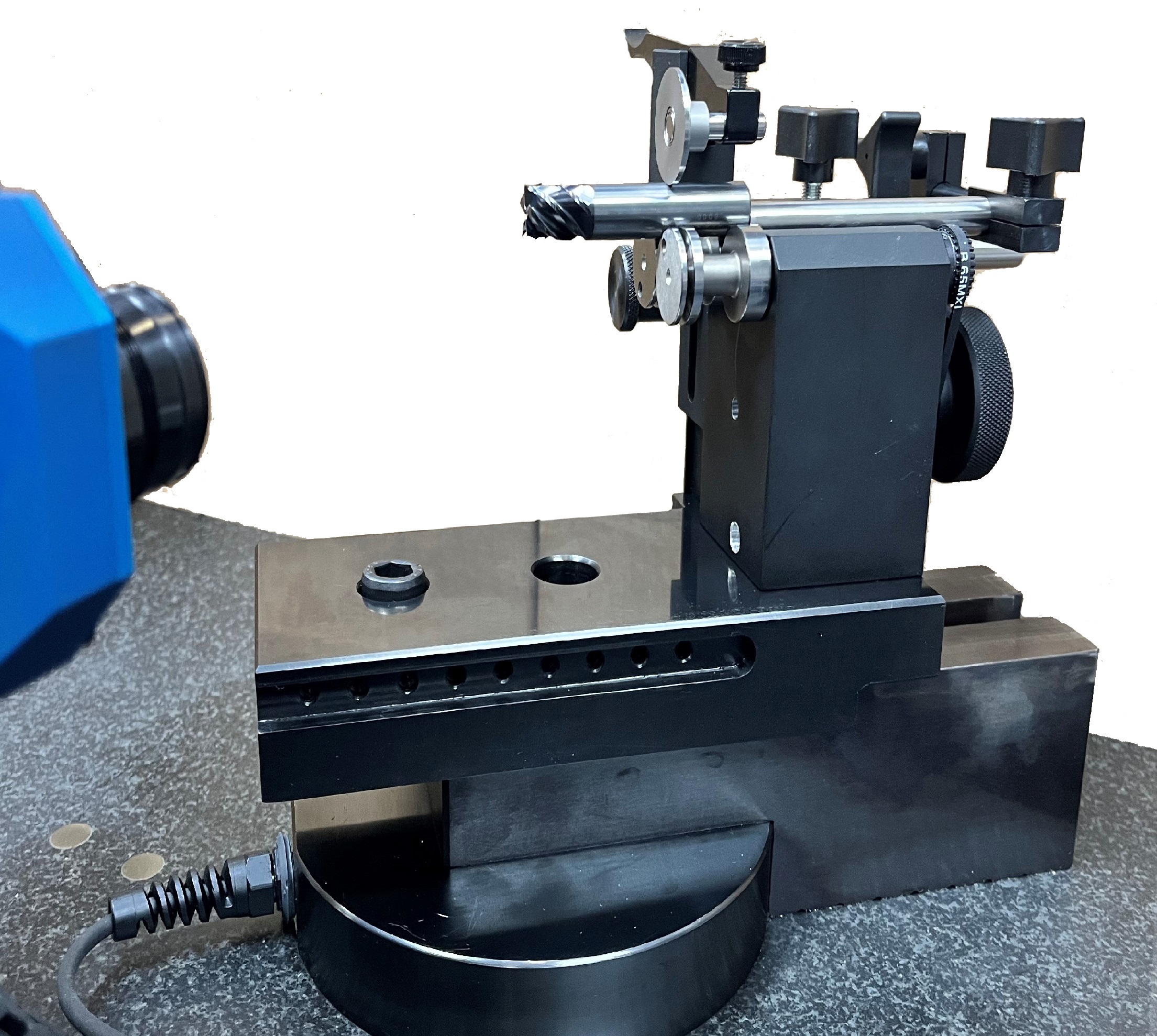

The PG concentricity fixture, also known as a 3 roller, provides a constant smooth part rotation that allows for easy and accurate measurements of the tool. All precision concentricity fixture are certified to be accurate within 2µ over the rollers.

Each unit includes an adjustable multi-position top arm yoke (top roller), a manual drive timing belt pulley system and a steel base plate to mount the fixture to the PG1000 base block.

The REACTION software includes 9 Edge Detection calculations which require the use of a concentricity fixture. This accessory is ideal for customers that want to measure diameter or radius using the Edge Detection feature in the REACTION software.

p/n 1000-571

Concentricity fixture for small & micro tools.

Includes precision ‘zero-style’ rollers, ‘zero-style’ top roller, backstop and base plate compatible with PG1000 base block.

Shank/tool size range: 0.010″ – 1.0+” (.25 – 25+mm).

p/n 1000-573

Concentricity fixture for a wide range of tool sizes.

Includes precision quarter plain rollers, top roller, backstop and base plate compatible with PG1000 base block.

Shank/tool size range: 0.125″ – 1.250″ (3 – 32mm).

p/n 1000-572

Concentricity fixture for larger tools.

Includes precision solid plain rollers, top roller, backstop and base plate compatible with PG1000 base block.

Shank/tool size range: 0.375″ – 2.0” (9.5 – 50mm).

PG Inspection Technologies reserves the right to change specifications and designs without notice.

Illustrations, data, dimensions and weights given in this brochure and on our website are for guidance only and cannot be held binding on the company.

Have a question?

We’re here to help.